The Difference Between Oxyfuel Cutting and Plasma Cutting and Choosing the Right One for Your Project

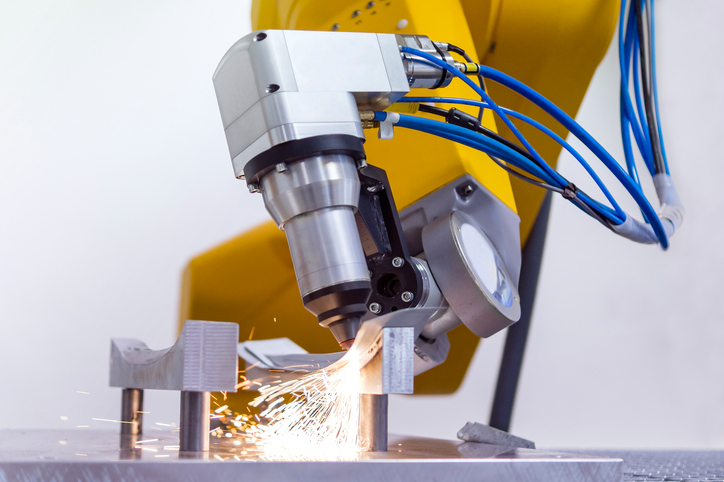

When it comes to automating production lines, robotic cutting systems are widely utilized across various industries. Manufacturers often face a critical decision: whether to go with robotic oxyfuel cutting or robotic plasma cutting for their specific needs. Both methods have their own strengths and limitations, making the choice dependent on the particular requirements of the project.

Understanding the underlying principles of oxyfuel cutting and plasma cutting is essential before making this significant decision. Each method operates on different physical principles, which directly impact its effectiveness and suitability for certain types of materials and tasks.

The Fundamentals of Plasma Cutting and Oxyfuel Cutting

Plasma cutting works by generating an intense stream of ionized gas, commonly referred to as plasma. This is achieved by channeling compressed air through an electrode, creating a highly energized beam capable of slicing through metal. The plasma's temperature can reach up to 20,000 degrees Celsius, enabling it to cut through most non-ferrous metals swiftly and efficiently. The process is particularly effective for thinner materials, offering clean cuts with minimal distortion.

Oxyfuel cutting, on the other hand, relies on a combination of oxygen and a fuel gas like acetylene to generate a flame hot enough to melt steel. Once the metal reaches its melting point, a high-pressure oxygen stream is directed at the molten pool, blowing away the liquefied material and completing the cut. This method is especially suited for thicker ferrous metals due to its ability to penetrate deeply and cleanly.

The Strengths and Weaknesses of Plasma Cutting vs. Oxyfuel Cutting

Plasma cutting shines when dealing with thin sheets of non-ferrous metals such as aluminum, copper, and stainless steel. Its primary advantage lies in its speed and versatility, allowing for rapid and accurate cuts. However, plasma cutting struggles with thicker materials and may not provide the precision required for intricate designs involving ferrous metals.

In contrast, oxyfuel cutting excels in handling thick steel plates and structural components. Its capability to deliver precise cuts in heavy-duty materials makes it indispensable in sectors like shipbuilding and construction. Nevertheless, oxyfuel cutting tends to be slower than plasma cutting and is less efficient for thin materials, often resulting in higher operational costs.

Choosing between plasma cutting and oxyfuel cutting ultimately depends on the nature of your project. If you're working with thin, non-ferrous metals and require fast processing times, plasma cutting is likely the better option. Conversely, if you need to handle thick, ferrous materials with precision, oxyfuel cutting should be considered.

Ultimately, the decision hinges on balancing factors such as material type, thickness, and desired quality of the cut. For those seeking comprehensive insights into robotic cutting technologies, exploring advanced solutions from companies like Genesis Systems Group can provide valuable guidance tailored to your specific needs.

For further reading, delve deeper into how Genesis Systems Group leads the field in robotic oxyfuel and plasma cutting innovations. Whether you're aiming to enhance productivity or achieve superior precision, understanding these cutting-edge technologies can significantly influence your success.

Posted in Robotic ApplicationsShaanxi WLB Auto Sales Co.Ltd. , https://www.wlbauto.com