The Difference Between Oxyfuel Cutting and Plasma Cutting and How to Pick the Best Option for Your Project

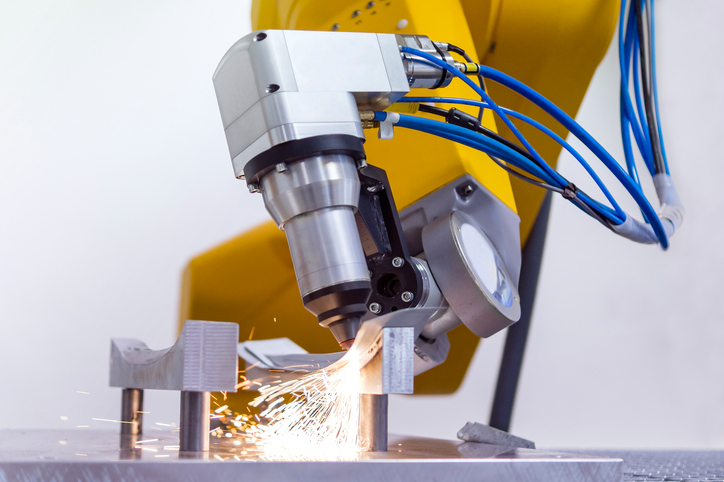

In modern manufacturing environments, robotic cutting systems are increasingly common. When it comes to automating production lines, companies frequently face a critical decision: should they use robotic oxyfuel cutting or robotic plasma cutting? Both methods have their unique strengths and limitations, making the choice dependent on the specific requirements of your project.

Before diving into the details, it's crucial to understand the core principles behind each method. Plasma cutting operates by creating a superheated plasma stream using an electrical charge and compressed air. This plasma is directed through a nozzle to cut through metal with remarkable precision and speed. On the other hand, oxyfuel cutting relies on a high-temperature flame produced by burning a mixture of oxygen and fuel gas. This flame preheats the metal until it reaches its ignition point, after which a powerful oxygen jet removes the molten material.

The Pros and Cons of Plasma Cutting

One of the standout features of robotic plasma cutting is its unmatched speed, particularly when working with thinner sheets of non-ferrous metals like aluminum or copper. Plasma cutting systems are highly efficient and can handle a variety of materials with ease. However, their effectiveness diminishes when dealing with thicker metals, especially those containing iron, due to limitations in cutting depth and precision.

The Strengths and Weaknesses of Oxyfuel Cutting

In contrast, robotic oxyfuel cutting shines when cutting through thick steel plates. It offers excellent control over the cutting process, resulting in clean, precise cuts that are ideal for welding applications. Unlike plasma cutting, oxyfuel cutting works exceptionally well with ferrous metals, which makes it a go-to solution for heavy-duty industrial projects. Nevertheless, it's slower than plasma cutting and less effective on thinner materials, where the risk of warping or deformation becomes significant.

When deciding between these two cutting technologies, it's essential to consider the nature of the task at hand. For example, if you're working with thick steel components and require robust welds, oxyfuel cutting might be the better choice. Conversely, if speed and versatility are your primary concerns, plasma cutting could be the superior option.

While both methods have their place in modern manufacturing, understanding the nuances of each can make all the difference. Whether you're automating a production line or tackling a custom project, selecting the right cutting technology ensures optimal performance and cost-efficiency.

For additional insights into robotic oxyfuel cutting and plasma cutting solutions, explore Genesis Systems Group's advanced offerings. Their expertise spans a broad range of industries, ensuring that you receive tailored guidance to meet your specific needs.

Published under Robotic ApplicationsZeekr X,Geely Zeekr X,Zeeker X Cream Color,Zeekr New Luxury Suv

Shaanxi WLB Auto Sales Co.Ltd. , https://www.wlbauto.com