I. Introduction

Valuable metal element is an important research direction in the field of mining and metallurgy complex biological leaching of low-grade deposits. There are few reports on the bioleaching of low-grade nickel- copper sulfide ore. Miller et al. conducted a bacterial heap leaching simulation experiment on low-grade nickel ore in South Africa. The leaching rate of nickel after leaching for 70 days was 30% to 50%. Southwood et al. studied some important parameters affecting the bioleaching of low-grade nickel ore, indicating that the physical and chemical properties of the ore, the permeability and porosity of the leach are the main factors affecting the leaching rate and the leaching rate. The presence of a large number of gangue hinders the nickel. Leaching. The work of the predecessors showed that the low-grade nickel-copper ore was treated by biological heap leaching, and the leaching rate was slow and the leaching rate was low. In order to further improve the leaching efficiency, it is necessary to experiment with other leaching methods to treat low-grade complex nickel-copper ore.

This paper discusses the experimental results of three different ways of bioleaching low-grade nickel-copper sulfide ore. Effect of Different bioleaching embodiment, results leaching conditions study has been completed based on, comprising: using ferrous ferrooxidans (the TF5) leaching of sulfide ore, pH value should be strictly controlled to 1.2 ~ 2.0; initial inoculum of bacteria should Maintained at 10 8 ~ 10 9 ∕g (cell ∕ ore); the appropriate pulp concentration is determined by the mineral sulphide content; adding appropriate amount of Thiobacillus thiooxidans (TT) is beneficial to the leaching process, to TF5: TT = 2 The ratio of 1 was optimally inoculated; the leaching rate of nickel and copper was the highest at a temperature of 35 °C. Experimental leaching methods include aeration agitation leaching, aeration agitation leaching, and column percolation leaching.

Second, the experiment

The ore samples used in the experiment were taken from the bottom of the Jinchuan No. 2 Mine. The main mineral components are nickel pyrrhotite, pentlandite and chalcopyrite. The ore contains 0.68% nickel, 0.34% copper and 0.022% cobalt . The experimental ore sample is divided into two sizes: -300 mesh accounting for 97% and -300 mesh accounting for 54%. The bacteria were obtained from Thiobacillus ferrooxidans and Thiobacillus thiooxidans provided by the Institute of Microbiology of the Chinese Academy of Sciences and used after further domestication.

Thiobacillus ferrooxidans was cultured in Leathen medium, and Thiobacillus thiooxidans was cultured in Starky medium at a temperature of 35 ° C and a shaking speed of 140 r ∕ min. The mixed bacteria are cultured with the original ore, and the mixed bacteria are composed of Thiobacillus ferrooxidans and Thiobacillus thiooxidans in a ratio of 2:1.

The nickel, copper and cobalt in the solution were analyzed by atomic absorption analysis and the leaching rate was calculated.

Third, the results and discussion

(1) Ventilation and leaching

The leaching was carried out at a pulp concentration of 5%, 15%, and 25%, and the leaching temperature was room temperature (about 30 ° C). The experimental procedure is as follows: when the slurry concentration is 5%, in a simple airlift reactor (outer tube diameter 3.5cm, center tube diameter 2.5cm, its central straight tube single bubble air), add 270mlLeathen medium, 15g ore (The particle size is -300 mesh, 97%) and then acid is added for prepreg. The pH was stabilized at about 2.0, and inoculation was carried out. The inoculum was 30 ml to adapt to the mixed bacteria. Finally, the air was leached, and the aeration rate was about 60 L∕h. The analysis results were sampled every 2 days. When the pulp concentration is 15% and 25%, the experimental procedure is the same, except that the inoculum amount is different due to the different solid concentration, and the ratio of solid to bacterial inoculum is 10 ml of bacterial solution per 5 g of mineral. The leaching results of nickel and copper for three different pulp concentrations are shown in Figure 1, and the slag phase analysis is shown in Table 1. The experimental results show that when the slurry concentration is 15%, the leaching situation is the best, the nickel leaching rate is over 95%, and the cobalt leaching rate is above 82%. During the leaching process, the stagnation period of bacterial growth is closely related to the concentration of the slurry, and the slurry concentration is the shortest at 5%.

Figure 1 Vented gas agitated bioleaching of nickel and copper

Table 1 Gas leaching results

When the aeration gas is leached, the ore particles are suspended in the leachate by the lifting of the gas stream, and thus are unevenly distributed in the leachate. The distribution of bacteria in the pulp is related to the distribution of nutrients, oxygen and carbon dioxide around the bacteria. The high concentration of the pulp must be supplemented with high concentrations of nutrients, oxygen and carbon dioxide for the bacteria to grow sufficiently. Therefore, there are obvious disadvantages in the aeration gas agitation experiment. The uneven distribution of the ore causes different growth environments of the various parts of the leachate, which restricts the growth environment of the bacteria, and directly affects the leaching rate and the leaching rate of the metal elements. When leaching low-grade nickel ore, due to the low sulfide content, the concentration of the slurry must be relatively high to be more conducive to the growth of bacteria, but the aeration gas agitation method is not suitable for the leaching of high pulp concentration, so the low-grade nickel ore is leached by this method. At this time, it needs to be carried out in a high-efficiency reactor, and this part of the work is under study.

(2) Ventilation and stirring leaching

Ventilation agitation leaching is characterized by the introduction of air leaching under electromagnetic agitation. The stirring leaching reactor was placed in a constant temperature water bath at a temperature of 35 ° C, a stirring speed of 300 r ∕ min, and an air passage rate of about 40 L ∕ h.

1. Aeration and stirring leaching of different pulp concentrations

The experiment was carried out under the conditions of a pulp concentration of 15%, 25%, and 30%. The leaching experiment was carried out at a concentration of 15% pulp: 140 ml of Leathen medium was added to the constant temperature water bath leaching tank, then 30 g of ore (-300 mesh accounted for 97%) was placed, acid was pre-soaked, pH was stabilized at 2.0, and 60 ml was inoculated. The bacteria were mixed and then aerated and leached. The leaching experiment was the same at 25% and 30% pulp concentration, and the inoculated bacterial solids ratio was 10 ml of bacterial solution per 5 g of mineral. Samples were taken every two days and the results are shown in Figure 2. The results of the leaching analysis are shown in Table 2.

Figure 2 Ventilation and agitation of nickel and copper at different pulp concentrations

Table 2 Ventilation and stirring leaching results under different pulp concentrations

Experiments show that the leaching results are best at 25% pulp concentration. The reason is that at 15% pulp concentration, the amount of sulfide per unit volume is small and does not provide enough energy for bacterial growth. Under the microscope, the number of bacteria was significantly higher than the 15% pulp concentration at 25% pulp concentration. The 30% pulp concentration is too high, and the strong shear force that hinders the growth of the bacteria causes the leaching rate to decrease.

2, different particle size aeration stirring leaching

The experiment was carried out at a pulp concentration of 25%. The ore was divided into two sizes, which were -300 mesh accounted for 54% and -300 mesh accounted for 97%. The experimental procedure was as follows: acid prepreg was carried out by adding 100 ml of Leathen medium and 50 g of ore in a constant temperature water bath leaching tank. After the pH was stabilized at 2.0, 100 ml of bacterial solution was added. The two experimental procedures were the same and the medium was continuously replenished to fix the solution volume at 200 ml. Samples were taken every two days for analysis. The results of the experiment are shown in Figure 3. Table 3 shows the results of the leaching.

Figure 3 Ventilation stirring to leach different sizes of nickel and copper

Table 3 Ventilation stirring leaching results at different particle sizes

The experimental results show that the smaller the particle size of the mineral, the better the leaching. During the leaching process, the acid consumption is significantly increased when the particle size is fine.

Ventilation agitation leaching has significant advantages over vented gas leaching. The mechanical agitation is used to make the ore distribution in the leachate more uniform, and the higher pulp concentration can be used, which is beneficial to the growth of bacteria. On the other hand, in the case of a high concentration of slurry, ventilation plus mechanical agitation produces a strong shear force, which is not conducive to bacterial leaching. Therefore, when leaching in this manner, the leaching rate is less than that of gas leaching. However, the proper combination of stirring speed and slurry concentration may increase the leaching rate of aeration agitation leaching, and is more suitable for leaching low-grade nickel-copper ore. However, the production cost of this method is relatively high. Because of the high gangue content of low-grade nickel-copper ore and the low content of valuable metals, only a shortened production cycle has better economic benefits. To this end, it is necessary to solve high-efficiency strains, shorten the growth stagnation period, and develop a highly efficient reactor with uniform distribution without excessive shear force.

(3) Column percolation leaching

The use of stirred leaching in low-grade nickel-copper ore will significantly increase the treatment cost, and in order to improve economic efficiency, consider the relatively low-cost bio- heap leaching. Column helium leaching is used in the laboratory to simulate heap leaching. In this experiment, a column glass reactor (diameter 2. 5 cm) was used, the ore size was controlled at -20 mesh to +40 mesh, the total weight of the ore was 100 g, and the column height of the leachate (pH=2) was about 20 cm, and the total volume was 4000 ml. The flow rate of the leachate is about 25 cm ∕h, there is no solution on the surface of the diafiltration column ore, and the temperature is about 25 ° C for cyclic leaching. The acid pre-dip was first carried out, and after the pH was stabilized at 2.0, 400 ml of the bacterial liquid was added. During the leaching process, the liquid evaporation portion was supplemented with Leathen medium. Sampling analysis was performed every 7 days, and the experimental results are shown in Fig. 4, and Table 4 is the leaching result.

Figure 4 Column percolation leaching nickel and copper

Table 4 Column percolation leaching results

![]()

After 28 d of leaching, silver ions were added as a catalyst to increase the leaching rate of copper in an amount of 1.2 mg ∕g (catalyst strontium ore). It can be seen from the experimental results that the leaching speed of the column leaching leaching experiment is very slow. During the leaching process, the Eh value of the solution is always at a low level, around 0.62 mV (SCE). Since the leaching process is slow and the pH value rises frequently, it is necessary to add acid supplement frequently to adjust the pH value, and the total acid consumption during leaching is 0.002 mol ∕g.

Percolation leaching is the lowest production leaching method, but because the ore has a fine particle size and is always in a static state, the leaching period is long and the leaching rate is lower than the first two modes. However, in terms of economic benefits, percolation leaching is the most promising application for industrial production.

Fourth, the conclusion

The bioleaching experiment of Jinchuan low-grade nickel-copper sulfide ore was carried out in three different ways, and the following conclusions were obtained:

(1) Ventilation gas leaching results were the best. After leaching for 20 days at 15% pulp concentration, the nickel leaching rate was 953.4%, copper was 48.6%, and cobalt was 82.6%.

(2) Ventilation and stirring leaching can be carried out at high pulp concentration, and the leaching period is the shortest. After leaching for 14 days at 25% pulp concentration, the nickel leaching rate is 80.2%, copper is 45.2%, and cobalt is 78.4%.

(3) The column leaching period has a long leaching period and a low leaching rate. After leaching for 49 days, the nickel leaching rate is 48.5%, copper is 37.5%, and cobalt is 33.6%.

Product Application

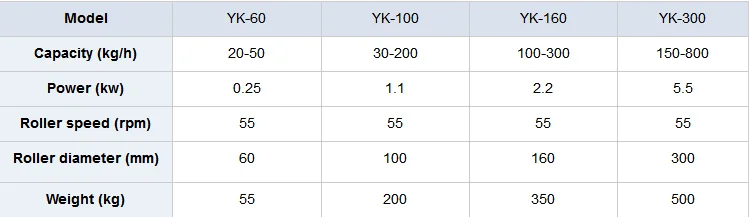

YK Oscillating Granulator (model: YK) is the process of making granule from wet material or dry material. It can be inline or operated as a single machine.

Working Principle

The material is fed from the top hopper. The oscillating roller crushes the dry lump and breaks them down into small grain or powder, which is passed through sieve hole. It also can extrude wet material into regular size granule via sieve hole by oscillating roller.

It can be widely used in Pharmaceutical Industry, Foodstuff Industry, Chemical Industry, etc.

CHANGZHOU SULI DRYING EQUIPMENT CO.,LTD.specializing in the production of Mixing Dryer, Spray Dryer, Granulation Dryer, Crushing Dryer, 3D Motion Mixer and V-shaped Mixer.

Swaying Granulator,Pharmaceutical Swaying Granulator,Stainless Steel Swaying Granulator,Powder Swaying Granulator

Changzhou Su Li drying equipment Co., Ltd. , https://www.sldrying.com