The production line of aerated concrete equipment produced by Yuhui Heavy Industry is mainly two production processes. These two processes are the fly ash aerated concrete block process and sand aerated concrete production line process. Combining advanced technology at home and abroad, the company's research and development of fly ash aerated concrete block and sand-filled concrete production line equipment and other aspects of technology to achieve the industry's outstanding level. Aerated concrete block is a kind of green made of river sand, lime and cement as main raw materials, aluminum paste as gas generating agent, raw material grinding, ingredient mixing, pouring gas, static stop cutting and autoclave curing. Environmental protection new self-insulating wall material. With the characteristics of light weight, high strength, durability, heat preservation, sound insulation, fire prevention, impermeability, and good anchorage performance, it has the advantages of convenient construction, strong machinability, ability to reduce the overall cost of the building, and increase the area of ​​use of the building. Widely used in industrial and civil buildings, it becomes a kind of wall material that thrives and has good performance. It is also a major new project. The description of the aerated concrete equipment production line can be based on the types of raw materials, quality, process characteristics of major equipment, etc., and adopt different processes for production. But under normal circumstances, sand-filled concrete is made of river sand, lime, and cement as the main raw materials, and gypsum and foaming agent are injected into the mold frame after being stirred, and after static oxygen foaming and solidification, they are cut into blocks of various specifications or The sheet is fed into an autoclave by a steaming car and is formed into a porous, lightweight, sand-filled concrete product under high-temperature saturated steam curing.

1. Thicken welded steel tubes, the thickness is at the top of CNC Router industry in China. The 4 X8 cnc router is the basic size, also available size of 5 X 10 cnc router, 6 X 10 cnc router etc size.

2. 3kw or more power HSD spindle or water cooling type. This one is with no maintenance, 6000-18000rpm.

3. The gantry is constructed of tubular steel with reinforcing ribs welded throughout the length of the column which results in a steady firm beam assembly. This quality engineering and workmanship result in smooth precision cutting.

4. Taiwan rail linear bearing ,double slippers,bearing heavy,working steadily.

5. Stepper motors are motion systems allowing to have a high positioning precision. With their high power already at low speed, their stall torque and the possibility to divide the steps in microsteps, stepper motors can provide direct and precise motions in a small volume.

Specifications of SCT wood Engraver CNC Router:

Applicable Industry:

1. Woodworking industry:

Three dimensional wave plate processing, cupboard doors, wooden doors, window processing, vedio game cabinets and panels,Computer table and furniture auxiliary processing.

Advertising signs, logo production, acrylic, plastic cutting, production of decorative materials, forming system module, etc.

3. Furniture industry,

Solid wood furniture, solid wood doors, decorative materials, computer tables, panel furniture, office furniture, wooden.

Option:

1) Dust collector

2) Vacuum table

3) Rotary ( for engraving round objects)

4) DSP controller

| Model | SCT-W1325 |

|

Work Piece size |

1300x2500x200 [mm] |

|

Working Axes |

3 axes, Horizontal & Vertical |

|

Machine Floor area |

3.5 [m]x 2.5 [m], |

|

Work Piece clamping |

Vacuum table |

|

MainUsed Materials |

Formica Topped plywood, 6-20 [mm] thick. MDF, 4-28 [mm] thick |

|

Tools Replacement |

Non-Automatic different Tools Can be used |

|

Working Speed |

15000 [mm/m],min. |

|

Rapid Travel speed |

30000 [mm/m], min. |

|

Sawdust Removal |

Required |

|

Working Accuracy |

±0.05 [mm], min. |

|

Repositioning Accuracy |

±0.05 [mm], min. |

|

Working Power |

AC220V/380V/50HZ |

|

Software Capabilities |

Artcam User Friendly, Supports English, 3D CAD format (STEP-), Optimization for maximal Raw material usage, quick set up. |

|

Noise Level |

85 [db(a)] max,, 88 [db(a)] max, for short time operations only. Measured Within a: 40 [m2] x 2.5 [m] max. Space |

|

Spindle |

3kw water cooling spindle |

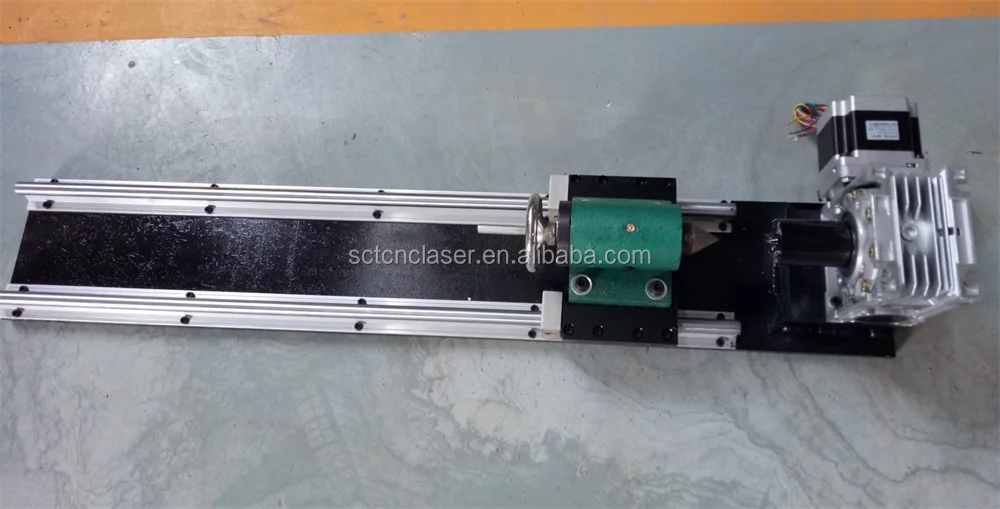

Rotary Axis for cylinder materials optional:

They are firstly greased thoroughly and packaged in a free-fumigation wooden crate. At SCT we strive to make your buying experience as convenient as possible. We work directly with shipping companies to ensure the best price for the shipment and we pass those savings on to you. Please notify salesperson at the time of your quote request if you wish to arrange for your own shipping method.

Guarantee

CNC Router–full 12 months back to base warranty on the router cnc and relevant manufacturers warranty on 3rd party add ons. This covers electrical and mechanical parts under `normal use`.

After-sales service

•Guarantee one year (except for consumable parts)

•Whole lifetime free service

•Technical support online or remote control

•Free tutorial and training courses (in video or in factory)

•Spare parts discount

CNC Router

CNC Router,CNC Wood Router,CNC Engraving Router,Small CNC Router

Shandong Sunrise CNC Machine Co., Ltd , http://www.scmcnc.com